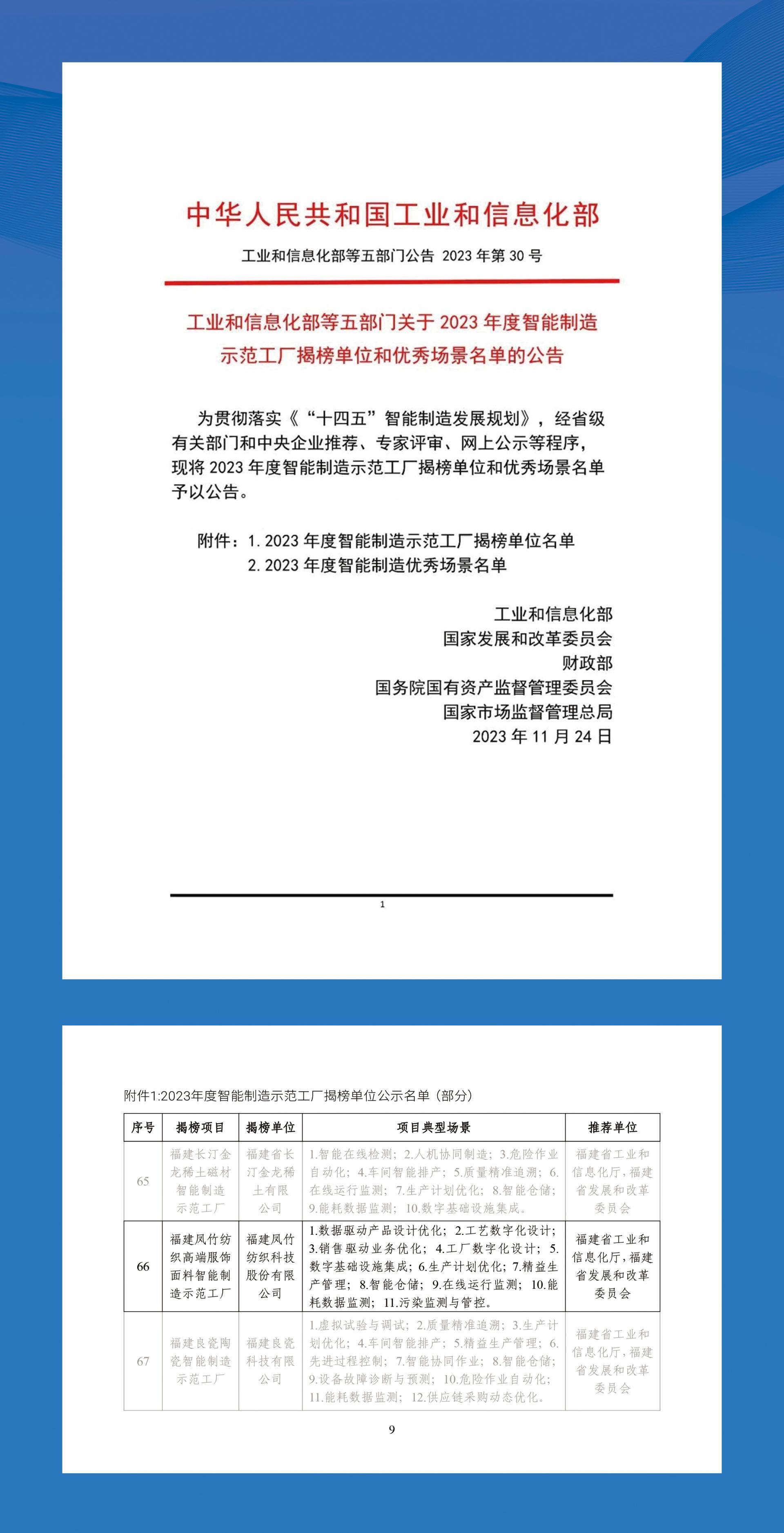

Major Breakthroughs on the List of 2023 National Intelligent Manufacturing Demonstration Factories

Release time:

2023-11-14

On October 26, the Ministry of Industry and Information Technology released a publicity document on the list of units and excellent scenes for the 2023 intelligent manufacturing demonstration factory. Jinjiang has a total of 4 units selected. Among them, Fengzhu Textile was selected as the 2023 intelligent manufacturing demonstration factory unveiling unit and is the only enterprise in Jinjiang selected as the intelligent manufacturing demonstration factory unveiling unit. As early as 2022, the two major scenes of "lean production management" and "energy consumption data monitoring" of Fengzhu textile digital demonstration factory were selected into the "excellent scene of intelligent manufacturing pilot demonstration" of the Ministry of industry and information technology ". The selection of the "2023 Intelligent Manufacturing Demonstration Factory Unveiling Unit" by the Ministry of Industry and Information Technology is a high affirmation of the achievements of Fengzhu Textile Intelligent Manufacturing.

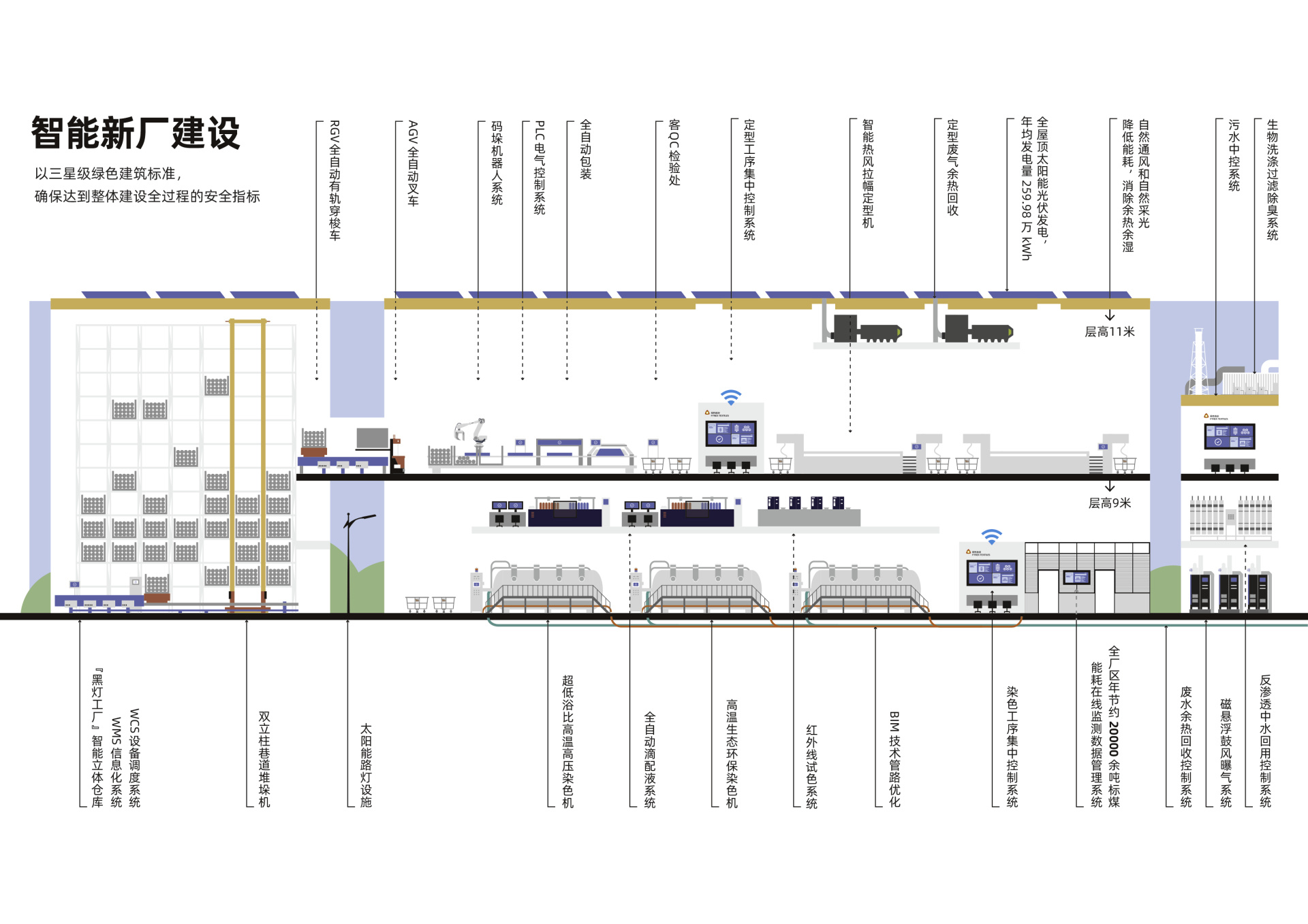

Green manufacturing and intelligent manufacturing have become the mainstream direction of the development of today's manufacturing industry. In order to promote the development of the textile industry to green manufacturing and intelligent manufacturing, Fengzhu Textile has carried out overall planning with high starting point, high standards and high requirements, invested 0.85 billion yuan in construction, introduced 25 intelligent and green high-end technologies and equipment, and built a new Anton green intelligent manufacturing factory. Through the planning and construction of intelligent manufacturing information system, the five elements of human, machine, material, energy and data are controlled, so as to realize the intelligent scheduling, adjustment and optimization of the whole production process from front-end procurement, production planning management to back-end warehousing and logistics, comprehensively implement the green intelligent manufacturing strategy, and realize low-carbon sustainable development.

1. actively promote intelligent construction and comprehensively improve operational efficiency

The company focuses on the green intelligent manufacturing strategy, faces the whole process of knitting fabric printing and dyeing production, starts from the aspects of procurement, production and storage logistics, fully recognizes the intelligent requirements of macro environment, customer market and production and manufacturing, and plans to form an intelligent factory overall architecture covering the integration of all elements such as basic equipment layer, process automation layer, production control layer, workshop MES layer to enterprise ERP layer and BI layer. Relying on the industry status and brand advantages, integrating the intelligent factory construction scheme developed by system integrators, software developers, intelligent equipment suppliers and intelligent manufacturing research institutes, a high-end clothing fabric intelligent manufacturing factory with an annual output of 50000 tons has been built, which is highly integrated with intelligent sensors, intelligent instruments and meters, networked control and analysis, online detection, remote monitoring and fault diagnosis systems to realize visualization of production process and predictability of production process, comprehensively improve the intelligent manufacturing level of clothing fabric printing and dyeing, and lead the development of intelligent manufacturing technology in textile printing and dyeing industry. After the project is put into production, the product defect rate and factory operating cost are reduced by more than 20%, the energy consumption per unit product is reduced by more than 10%, the product development cycle is shortened by more than 30%, and the overall production efficiency is increased by more than 20%, realizing the unity of intelligent manufacturing and green manufacturing.

2. the implementation of green energy-saving projects to achieve energy efficiency, water efficiency lead

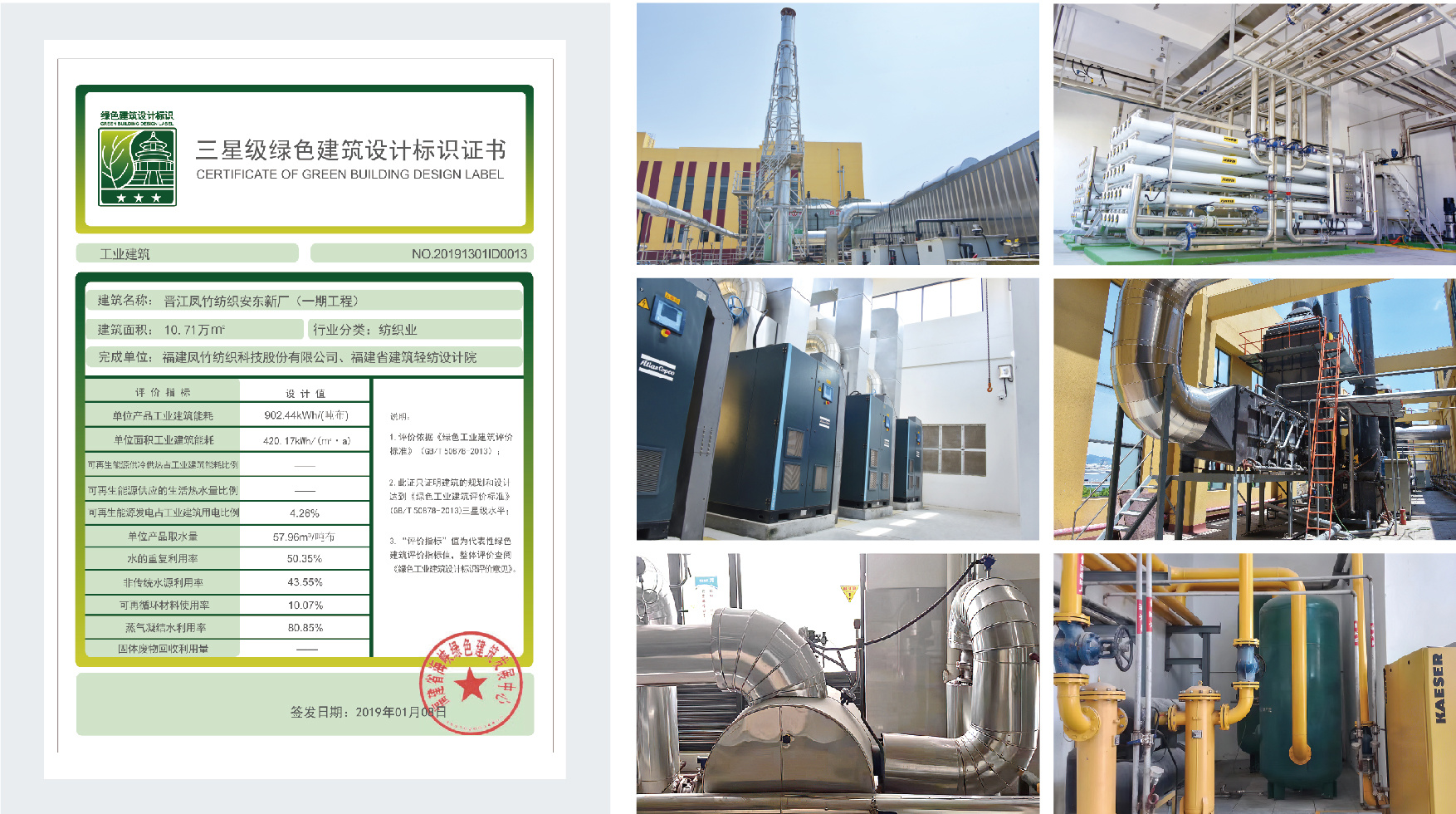

The company Anton new factory is planned and designed according to the national "Green Industrial Building Evaluation Standard" to realize the integration of construction and design. It is the first three-star green industrial building in Fujian Province and the first three-star green industrial building in the national printing and dyeing industry. The application of energy online metering instruments develops an online metering and control system for production energy from the three levels of enterprise-workshop-key equipment to realize automatic, visual and systematic management of energy for enterprises, to carry out real-time monitoring and analysis of energy and corresponding equipment at various production points, to adjust energy distribution, to maximize energy cost saving, and to achieve the purposes of safe energy use, rational energy allocation and energy saving. Plan to implement the application of solar photovoltaic power generation facilities, replace part of the thermal power, reduce the traditional power consumption, and further enhance the clean and low carbon energy consumption.

Develop a remote operation and maintenance system for the exhaust gas treatment equipment of the setting machine based on the Internet of Things, remotely monitor the operating parameters of the decentralized treatment equipment, and develop functional modules such as remote alarm for abnormal conditions, maintenance optimization scheduling, and operation quality assessment to improve operation and maintenance efficiency and reduce operation and maintenance costs. The sewage treatment plant adopts UF + RO reverse osmosis membrane reuse technology, and is equipped with a reclaimed water reuse system with a water yield of 6500 tons/day, with a sewage treatment reuse rate of 50%. Development and application of efficient heat recovery technology and equipment to achieve efficient recovery of waste heat energy, heat recovery rate of up to 60%. The steam jet heat pump system is used to realize the steam cascade utilization in the workshop, so as to reduce the unit consumption of steam equipment. In 2022, the company has been selected as the energy efficiency leader of key energy-using units in Fujian Province and the water efficiency leader of key water-using enterprises.

3. Rely on Technological Innovation to Improve the Level of Green Product Design and Manufacturing

In 2006, the company's technology center was recognized as a "national enterprise technology center", the first "national enterprise technology center" in the knitting industry in the country, and also a provincial enterprise technology center in Fujian province and a provincial industrial design center in Fujian province. It has Quanzhou expert workstation, Jinjiang postdoctoral forum and other technological innovation platforms. The testing center under the technology center passed the "CNAS" accreditation of China National Accreditation Committee for conformity Assessment in 2006, and is the first textile testing laboratory in the province. At present, the company has built a technology research and development platform that integrates independent research and development, external introduction, internal and external cooperation, industrial alliance, industry-university-research combination and other forms of coexistence. In 2019, the company won the technology innovation demonstration enterprise of the Ministry of Industry and Information Technology. The company is the first in the industry to pass the ISO9001 quality management system and ISO14001 environmental management system and ISO45001 occupational health and safety management system certification, the main products by the international ecological textile Oeko Tex Standard100 certification, the United Kingdom ITS company Intertek ecological product class I certification, green leaf certification and global textile organic cotton certification.

In addition, the company also actively participated in the drafting and formulation of green standard policies. It has participated in the drafting of a total of 8 standards related to green design, green products and green manufacturing, including 1 national standard, 1 industry standard, and 6 group standards. "Fengzhu brand" knitted fabrics are green and environmentally friendly mid-to-high-end products, and have been awarded the honors of "Chinese Famous Brand Products" and "Fujian Famous Brand Products" respectively. From 2019 to 2021, the Company's sales of green products were all above $0.6 billion, with green products accounting for 79.56, 72.77 and 86.78 percent of sales, respectively. In 2019, the company was selected into the "fourth batch of national green factories" of the Ministry of Industry and Information Technology. In 2020, the company's six main products (pure cotton single-sided cloth, pure cotton double-sided cloth, pure cotton spandex cloth, polyester cotton single-sided cloth, polyester cotton double-sided cloth, polyester cotton spandex cloth) were selected into the "fifth batch of national green design products list" of the Ministry of Industry and Information Technology ".

Through the implementation of green intelligent manufacturing strategy, the company improves labor efficiency, reduces production energy consumption, and realizes green low-carbon sustainable development. In the future, we will continue to give full play to the advantages of brand and technology, continue to lead the further development of green manufacturing technology in the textile printing and dyeing industry, promote the transformation and upgrading of the textile printing and dyeing industry to the direction of green and intelligent manufacturing, and make more contributions to the green and intelligent development of the textile printing and dyeing industry.

* Text source network forwarding, if there is infringement, please contact delete

Key words:

Intelligent manufacturing, demonstration factory

Information release

Fengzhu textile headquarters service telephone:0595-8205 0055

Insider Trading Report Phone:0595-8565 6506 Miss Chan Mei-jin (Secretary of the Board)